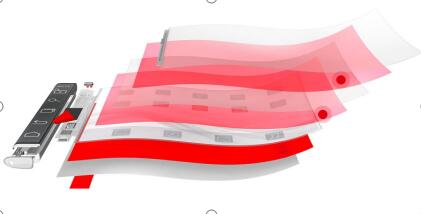

Bent, folded or curled, the potential for flexible OLED displays is huge. Plastic, organic OLED displays are thinner, lighter and more flexible than LCDS. Unlike LIQUID crystal displays (LCDS), OLED displays do not require backlighting but are brighter. However, for the small bending radius required by smart phones, foldable display modules face greater challenges in materials and technology. Each layer of the foldable display needs to be flexible and transparent, including touch panels, touch sensors, polarization mirrors and cover panels. In addition, all layers need to be very durable and ensure that they can withstand about 100,000 folds in the average smartphone life cycle.In terms of die-cutting, we collaborate with manufacturers that use acrylic foam and PE foam tapes as raw materials. Our products are specifically designed to meet the needs of window paste and die-cutting processes. Through a series of strict tests, they are capable of satisfying the requirements of the next-generation flexible display technology. These include static stress tests on different component materials during folding and dynamic stress tests in the unfolded state.